This is the upcoming revolution in electric car batteries

Large international research centers such as the Massachusetts Institute of Technology (MIT) are making advances at full speed in their battery research, with the aim of forever replacing batteries that use rare minerals and contaminants with others using more abundant and biodegradable materials.

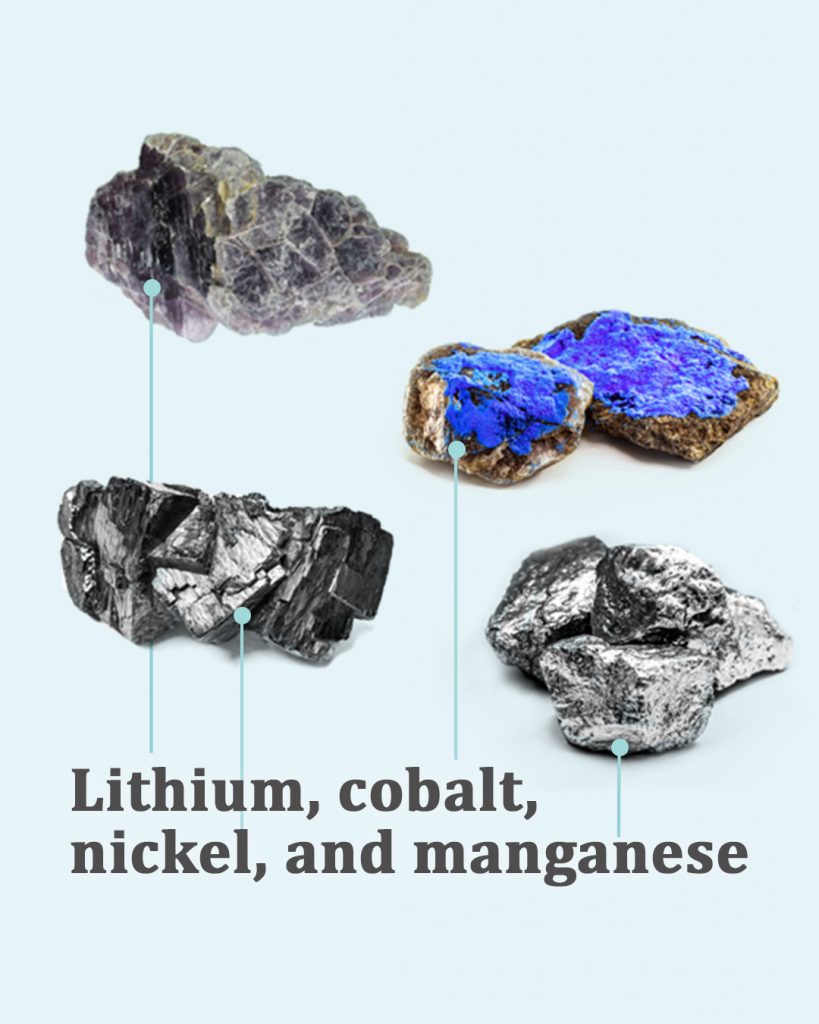

The cards are on the table and the starting gun has sounded. Cobalt, nickel, manganese, and lithium are the targets for scientists who are developing the batteries of the future. And experts believe that we can and must do without them.

According to statistics from World Mining Data, the Republic of the Congo controls around 70% of world cobalt production, while Indonesia, Chile and Russia control just over half of nickel production, and Australia and Chile dominate almost 75% of lithium mining.

For its part, the international supply of manganese depends on South Africa and Gabon, and a recent study by researchers at Carnegie Mellon University led by Anthony L. Cheng has found that China can easily interfere in the distribution of many of the most used battery minerals.

As can be seen, it is not only that nickel, cobalt, lithium, and manganese are more polluting and more difficult to recycle than the organic materials that could power batteries of the future. The issues also lie with their prices and supply, precisely because production and distribution are highly concentrated in a few hands and, because they are scarce, they are also more volatile when demand increases.

And that is exactly what impacted the balance sheets of the giants of the automotive sector last year, after a 65% increase in battery purchases in 2022 and a 40% increase in 2023, which led them, in the summer, to a supply crisis. Now, although the most used batteries continue to be made from nickel, manganese and cobalt, the need to diversify has become so overwhelming that manufacturers are beginning to incorporate others in their vehicles, such as lithium and ferrophosphate batteries, which provide about half the energy storage capacity in the same space.

Álvaro Luna, a professor in the Department of Electrical Engineering and the Higher School of Industrial, Aerospace and Audiovisual Engineering of Terrassa (ESEIAAT) at the Polytechnic University of Catalonia, explains that “laboratories are trying to offer alternatives to battery materials that are problematic from the point of view of geopolitics, supply, and environmental impact”. And, more specifically, he points out, “they want to replace cobalt, nickel and lithium with organic materials such as carbon and sodium.” And it’s not easy.

A huge challenge

According to the expert from the Polytechnic University of Catalonia, “current batteries, based mostly on lithium, offer very good results both in the charging cycles and in energy density and power.” Charging cycles are the number of times that batteries can be charged and depleted without long-term problems, and the density and energy power refers to the capacity of the batteries to store energy in a small space and provide it quickly during the starting, running and accelerating of electric vehicles.

However, organic materials seem very promising. And not only for environmental, geopolitical and supply reasons. As Antonio García, a researcher at Clean Mobility &

Thermofluids at the Polytechnic University of Valencia, points out, “organic materials can present greater thermal stability and lower risks of overheating, which can reduce the chance of fires or explosions.” In addition, he continues, “they are less toxic, which improves safety during manufacture, use and disposal.”

The expert from the Polytechnic University of Valencia also remembers that the race to find alternatives has already begun. Thus, he clarifies, “research presented by the University of Yamagata has identified up to 460 new organic compounds with a theoretical ability to achieve energy densities similar to those of materials commonly used, while researchers at Oak Ridge National Laboratory have conducted an extensive review of materials that could be compatible within a lithium-ion battery.”

Álvaro Luna, professor at the Polytechnic University of Catalonia, also adds to the list the advances in carbon batteries made by the company Power Japan Plus and the first results of research being carried out by MIT for Lamborghini. In this last case, they have advanced with a battery that, although it would continue to be based on lithium,would include a cathode made of organic materials instead of cobalt or nickel. The cathode is the electrode that carries the negative charge of the battery (the one that carries the positive charge is called anode).

According to MIT researchers, organic materials would make it possible to have cheaper batteries than the cobalt ones used in electric cars, and they would conduct electricity at similar speeds. The new batteries, they claim, also boast comparable storage capacity, and can be charged faster.

The expert from the Polytechnic University of Catalonia says that “international research is promising both in terms of electrodes, which carry the positive and negative charge, as electrolytes”, which are the solution—lithium, until now—where the ions ‘swim.’ Additionally, he clarifies, “all this research could converge and offer us, within a few years, mostly organic batteries for electric vehicles.”

For his part, Antonio García, researcher at Clean Mobility & Thermofluids at the Polytechnic University of Valencia, remembers that “the synthesis methods of the organic materials are still in early stages, which is why significant investment is required to continue to develop them.”

Furthermore, he continues, “despite the advantages, it is important to keep in mind that batteries with organic cathodes [such as those being developed by MIT] also face challenges, such as long-term stability, solubility in electrolytes and electrical conductivity. As research and development advances, these challenges can be addressed to make lithium-ion batteries with organic cathodes a viable and competitive alternative.”

Be that as it may, what is clear is that the main laboratories in the world, sometimes funded by automotive giants, have embarked on an amazing race for the future of electric mobility that involves the development of revolutionary batteries.

These organic batteries should help, at least, diversify and stabilize supply, to mitigate the dangerous frictions of geopolitics, to considerably reduce environmental impact and keep the costs of production, not only of cars, but of all zero-emissions means of transport, which includes everything from buses to motorcycles and scooters.

The starting signal has already sounded and there are billions of euros at stake. And there are many who wonder who and especially when will these laboratories find that ‘magic key’ that will help us protect and take care of the planet.

Write: Gonzalo Toca